![]()

AFRY

Company Description

AFRY is a European leader in engineering, design and consulting services with a global reach. It works to accelerate the transition to a sustainable society.

They have 17,000 experts in infrastructure, industry, energy and digitalisation, creating sustainable solutions for future generations.

ADDRESS: Avda. de Ranillas Nº 1D Planta 2 Oficina C 50.018 ZARAGOZA

PHONE: (+34) 976 249 606

E-MAIL: info@cognit.es

https://cognit.es/

AFRY

AFRY Services

- Integrated Environmental Authorizations – drafting, modification or processing

- Environmental licenses – processing

- Discharge declarations

- Calculation of sanitation fees

- Greenhouse gas (GHG) emissions reports

- Environmental risk analysis and monetisation

- Environmental and sustainability reports

- Carbon footprint calculations by ISO 14067 and other standards.

- Water footprint calculations according to 14046 and other standards

- LEED certificates

- Energy certificates

- Energy audit for compliance with RD 56/2016

- The legalisation of industrial facilities: low voltage, high voltage, fire protection, RITE, …

- Technical-legal-financial due diligence

- Implementation of ISO 9001 quality systems

- Implementation of ISO 14001 environmental systems

- Implementation of energy management systems ISO 50001

- Implementation of water management systems ISO 46001

- Maintenance of management systems

AFRY

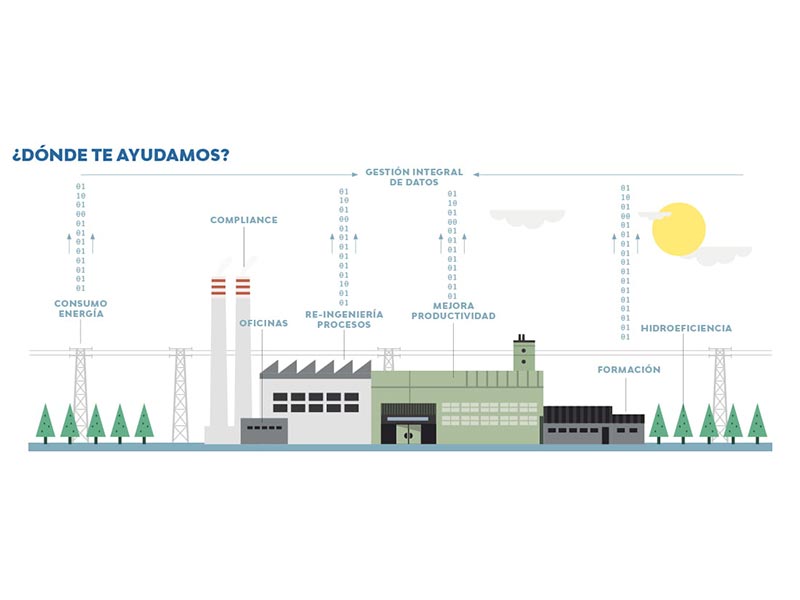

Energy audits

- Monitoring of energy and water consumption

- Water and energy consumption management system implementation

- Outsourcing of water and energy management

- Negotiation and management of gas and electricity supply contracts

- Predictive maintenance: thermographic audits, pumping system performance, verification of auxiliary systems operation, …

- Savings verification according to IPMVP protocol

- Zero discharge

- WWTP/ETAP optimization

- Capture, management and storage of process data

- Development of dashboards with Business Intelligence tools.

- Implementation of process historians in industrial plants

- SCADA programming

- Implementation of Six Sigma continuous improvement systems at the corporate and operational levels.

- Six Sigma training at all levels

- Implementation of statistical process control systems

- Process modelling and simulation

- Process optimisation through Digital Twin modelling

- Monte Carlo analysis focused on minimising errors and risks in the process.